Mazda Develops Plastic Molding Technology Which Reduces Consumption of Plastic Resins by 30 Percent

As part of its efforts to reduce vehicle weight, Mazda Motor Corporation has developed a new plastic molding technology that enables a substantial reduction in the weight of plastic parts used in vehicles. This plastic molding manufacturing technique cuts the consumption of plastic resins that are used as raw material by approximately 20 to 30 percent, with associated reductions in vehicle weight.

The most common manufacturing method for producing automobile plastic parts is injection molding. Mazda's improved injection molding process involves mixing supercritical fluid*1 (SCF), made from common inert gases such as nitrogen or carbon dioxide, with the plastic resin raw material. The process utilizes a particular characteristic of SCF to mix readily with other substances at the molecular level to raise the fluidity of the liquid plastic resin and cause it to expand rapidly when injected into a mold. As a result, smaller amounts of the raw material resin are needed to fill molds.

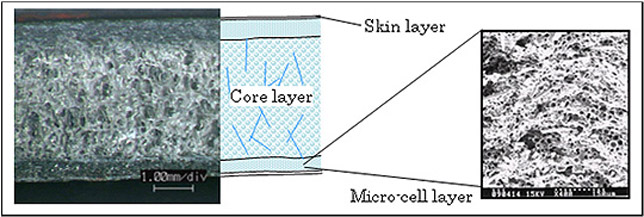

Furthermore, by using a "core back expansion molding process*2" – which enables thicker parts to be manufactured using less plastic raw material – Mazda has successfully developed plastic with a multi-layer structure. The bubbles in the outer layer of the plastic are kept microscopic to ensure each part has the necessary strength and rigidity, while the size of the bubbles in the core layer can be freely adjusted to reduce its density as desired.

With this proprietary technology, substantially less material is needed to manufacture plastic parts that are lighter and have equal or greater strength and rigidity characteristics compared to conventional, non-foamed parts.

This plastic foam molding technology can potentially be applied to nearly all plastic parts used in vehicles. Because the core back molding process enables control of the foam's structure, it is possible to add extra value by enhancing the heat insulation and acoustic characteristics of plastic parts.

Conventional plastic foaming methods use a gas formed through the thermal decomposition of organic and inorganic compounds. However, through the use of SCFs, Mazda's foamed resin molding technology does not result in adverse effects from residual chemical compounds, has a smaller impact on the environment, and produces parts that can be easily recycled.

*1 A supercritical fluid is any substance at a temperature and pressure above its thermodynamic critical point. It can diffuse through solids like a gas, and dissolve materials like a liquid.

Compared to their natural gaseous forms, nitrogen and carbon dioxide, as supercritical fluids, increase the solubility of plastic resin and enable it to form foam with a standardized micro-cell structure.

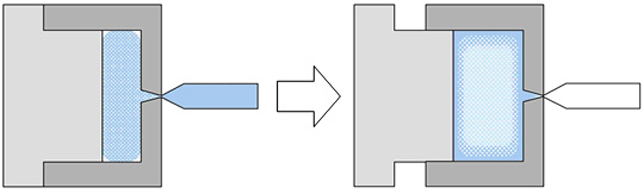

*2 ‘Core back' expansion molding is a form of injection molding. Once the foamed resin has filled up the mold, the volume of the mold is increased, causing the foam to expand. This means larger plastic parts, with low density and good rigidity, can be made from the same volume of plastic resin.

Reference materials

Multi-layer structure of newly developed foamed resin

Core back Expansion Molding

| Liquid resin infused with the supercritical fluid foaming agent is injected into a thin mold where it expands quickly to fill the space. |

After a certain period of time, the back of the mold is partially extracted (core back) to form the multi-layer structure. |