Antonov develops low cost gearbox for the low cost car

Antonov, the automotive technology company, is returning to first principles in order to develop the radical low cost transmission systems required for ultra low cost cars.

Antonov, the automotive technology company, is returning to first principles in order to develop the radical low cost transmission systems required for ultra low cost cars.

"We have unique experience of mechanical automatic shifting and alternative launch systems gained over almost 20 years," says John Moore.

"Such systems are ideally suited to the development of low cost automatic gearboxes much needed for the low cost vehicles required for emerging markets.

"Minimum cost can be achieved through the use of innovative technology and design and a careful review of the technical functions required.

"Above all the transmission must be simple, low cost, reliable and repairable. And if possible this means no pneumatic or hydraulic controls, minimal components and only the simplest of electrical systems.

"The transmission must also ensure ease of use for inexperienced drivers trying to cope with heavy traffic and be able to handle a wide range of vehicle payloads."

In seeking out viable up-to-date technical solutions, Antonov is exploiting its earlier inventions and innovative engineering roots. The company started in 1990 with a simple three-speed mechanical transmission, which evolved to four speeds with progressively more functionality to achieve a high quality shift. This evolution was driven by the need to achieve class competitive performance at reduced cost.

"The challenge today for the low cost car is to maintain only essential functionality," says Moore.

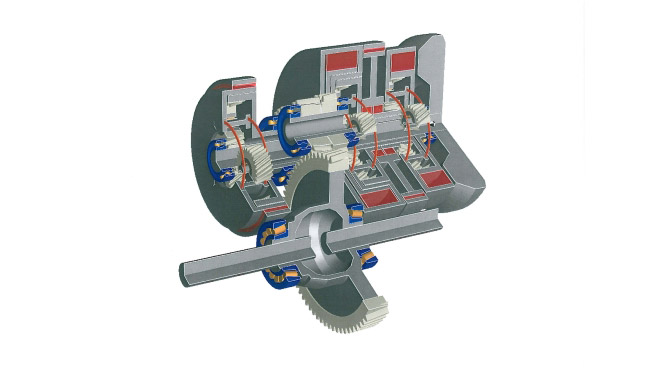

Antonov's underlying automatic transmission concept uses its original and pioneering patented shift system, which the company is also currently employing for a number of ancillary two-speed applications including alternators, superchargers and engine front-end pulleys – all designed to make modern engines more energy efficient and to facilitate the powertrain downsizing trend and increased electrical loads imposed on modern vehicles.

The Antonov shift system is implemented through a combination of centrifugal forces and the axial thrust from helical gears. The elegant simplicity of the system is its use of purely mechanical forces already present in meshing gears.

The principle can be extended to produce a simple low cost yet highly robust and efficient three or four speed automatic transmission system.

Antonov's latest thinking on low cost transmission systems not only builds on its original concepts, but adds years of experience and new ideas to radically simplify the gearbox with respect to launch and shift systems as well as considering the important issue of powertrain and vehicle integration.

A range of alternative launch systems is being considered including a torque converter and various clutch systems including a centrifugal mechanism and stationary magnetic powder clutch.

"A low cost torque converter, for example, can be integrated with the engine to avoid the need for a separate transmission oil pump, circuit and cooler," says chief engineer Simon Roberts. "A torque converter provides an excellent launch mechanism for a vehicle and allows it to creep along in slow moving traffic – two essential requirements for emerging markets. Efficiency issues are mitigated by having a direct drive for high ratios and only taking the drive through the converter for low ratios."

In essence, Antonov proposes the use of the simplest possible three or four speed systems depending on the application and precise requirements of each car maker approaching the company as a client.

"Each gear can be selected by a mechanically applied band brake and the whole system splash lubricated to eliminate the need for a pump," says Roberts.

"The brakes across one-way clutches can be eliminated provided the vehicle has sufficient brake capacity to avoid the need for engine braking.

"Shift calibration can be maintained very simply by use of electric solenoids, which only require simple on/off control from a throttle switch and can replace hydraulic pistons.

"And, if required, we can dispense with electric solenoids and hydraulic pistons altogether and employ a purely mechanical means for shift control, making use of direct linkage from the throttle to alter the shift point."

To help facilitate the continued commercialisation of its patents and intellectual property, Antonov has recently opened a new engineering centre near Warwick, which taps into the UK's wealth of automotive engineering know-how and experience and is close to other automotive technology specialists and sub-suppliers.

The new facility has allowed the consolidation of all Antonov product development activity onto one site and the expanded engineering team has helped strengthen its design services to the automotive industry and in particular the export of those services abroad.

The new premises were particularly necessary for the development of Antonov's full electronically-controlled six-speed gearbox, which is the subject of on-going joint venture negotiations with Loncin in China; the development of its ultra low cost three- and four-speed automatic transmission systems; and the two-speed automatic mechanical module which is already in production as a self controlling mechanical drive for a dual-speed supercharger, with additional applications to engine front end accessory drives also under development.

"Antonov can offer a high level of continuing innovation through its motivated and capable team," says Moore. "Clients globally demand reliable programme delivery and we're achieving this through the application of the latest computer-aided design and engineering combined with prototype test and development processes to world-class industry standards."